|

|

|

Advanced Technology of Combined X-ray and Laser Imaging Detection of Bone Fragments and Contaminants in De-Boned PoultryThis research develops a new technology for sensitive and accurate detection of bone fragments and foreign materials in poultry fillets on de-boning lines. The technology employs the synergisms of X-rays and laser imaging techniques that can detect in much great accuracy and sensitivity than traditional x-rays. It can sensitively and accurately detect all frequent and hard to detect bones such as fan bones, pulley bone fragments, and metals as small as 1/4 of a staple pin leg. Based on on-line demonstrations to prominent poultry processors, it is by far the best than any existing x-ray bone detection technology.

The United States produces over 13.2 billion pounds of boneless chicken meat annually (USDA, 2000) and consumers are increasingly demanding safe, high-quality boneless meat at a low cost. Accurate and rapid detection of bone fragments and other hazards in poultry meat has great urgency. Traditional x-ray technology has limited success mainly due to its inability to consistently recognize bone fragments in meat of uneven thickness. This project has developed a technology that integrates x-ray imaging with laser 3-D imaging to compensate for the uneven thickness of poultry meat. The new technology enhances the x-ray accuracy in bone fragment detection and augments the inspection system’s capability to rapidly and accurately detect bone fragments or hazards.

According to a major poultry company, the existence of bone fragments in de-boned chicken fillets is the No. 1 customer complaint. Strong demand was initiated from the poultry industry for increased food safety and quality of boneless chicken meat, reduced customer complaints, and improved cost-effective productions through technological advancement. In many modern poultry processing plants today, dozens of workers sit beside conveyors de-boning and inspecting poultry by hand. Typically, a crew on each line must check carefully to ensure that each meat product is free of bone fragments. Because the bone fragments are hard to find visually, each chicken breast is squeezed by hand in an effort to feel the bones. The meat is chilled near freezing to prevent microbial growth. Working nearly 8 hours a day, hands inevitably become numb, reducing the effectiveness of the inspection process.

Results from this study can advance x-ray technology in food inspection and promise to improve the quality, safety, and cost-effectiveness of US poultry products. It has a positive impact on the competitiveness of United States’ poultry in the global market.

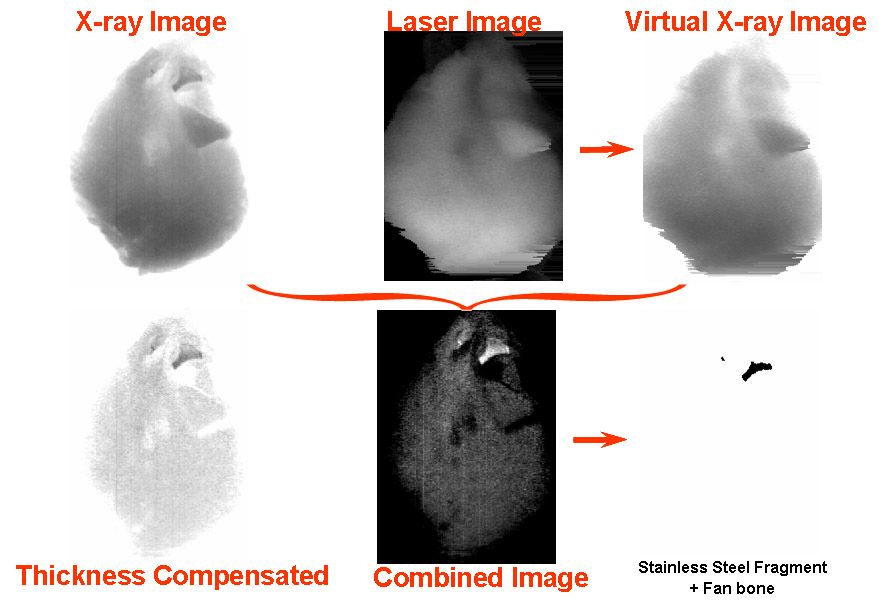

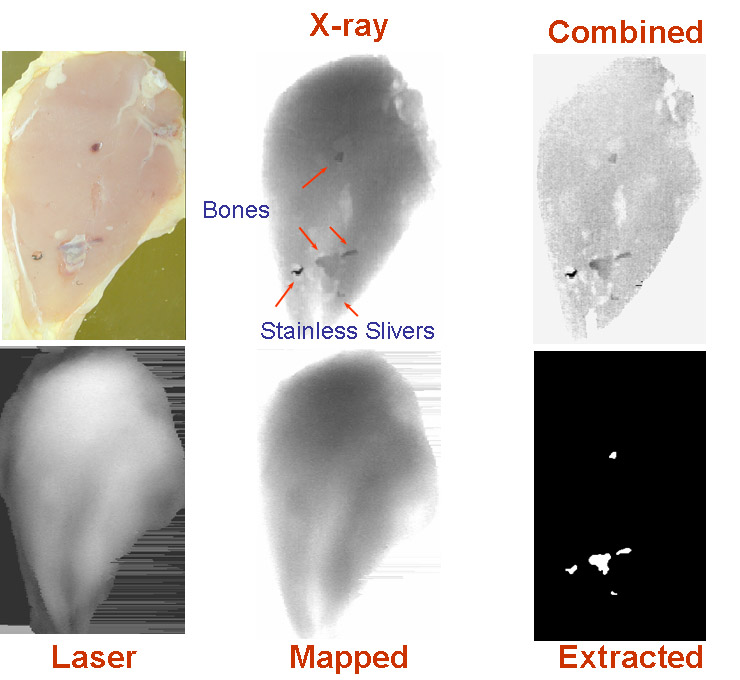

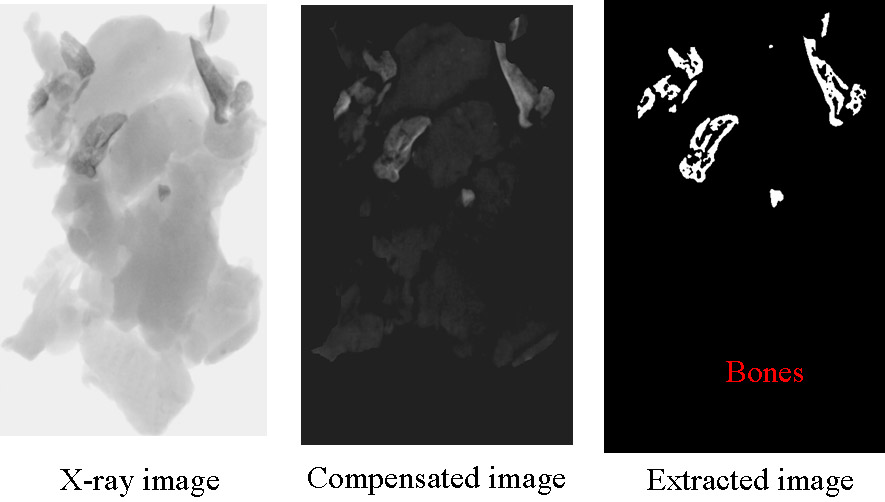

Results of x-ray and laser sensing to eliminate false patterns and achieve accurate detection. (a) x-ray image, (b) laser range image, (c) virtual x-ray image from (b), (d)(e) combined image, and (f) segmented image. The x-ray image has some inclusions – some are clear and some are not. The technique clearly reveals the inclusions.

|

| [Home] [Biography] [Research] [Teaching] [Industry Exp.] [Lab. Personnel] [Collaborators] [Publications] [Links] |