|

|

|

Identification of Walnut Shells by Reflectance and Fluorescence Imaging Techniques

Walnut shell discrimination is a very important step in the processing of shelled walnuts. The USDA has set forth very strict standards that allow no more than 0.05% shell or foreign material by weight in any grade of shelled walnuts. Even a small amount of hard shell mixed in with the much softer walnut meat would result in a very undesirable product. In processing plants, walnuts are first compression cracked and then separated by size. A large majority of the shells (more than 90%) are then removed by air lathes that blow away the lighter shells while leaving the heavier meat of the walnut. The final step is to remove any remaining shells by hand in order to reach the quality level required. This is a very tedious and difficult process because shell and meat fragments can be very similar in size and color. A machine vision system would reduce labor costs and eliminate errors due to boredom or distraction of employees.

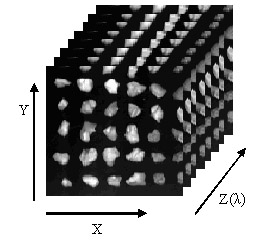

Reflectance and fluorescence imaging techniques were evaluated for their potential to be used to discriminate walnut shells from the edible meat portion. Reflectance techniques proved to be only marginally useful for identifying the outside of shells, and failed to identify the inner portion of shells. The image data acquired by the hyperspectral system are arranged as a three dimensional image cube, with two spatial dimensions and one spectral dimension, as shown in Figure 1. The pixels in the image cube can be defined as P(m,n,i), where m and n are the spatial indices, and i is the index of the spectral band. Under this framework, each point on the 2D image plane is defined as an N dimensional vector Q(m,n), where N is the total number of spectral bands and (m,n) identifies the spatial location.

Testing of this method resulted in 100% identification of walnut shells with little of the meat falsely identified as shell. These results meet the USDA's standards that require shelled walnuts to be 99.95% free of shell fragments. Such a technique shows potential as a less expensive alternative to current discrimination techniques.

Figure 1. A typical image cube generated by the hyperspectral imager, with two spatial dimensions X/Y, and one spectral dimension Z. The pixel in this image cube can be defined as P(m,n,i), where m,n, and i are the indices in the two spatial dimensions and one spectral dimension respectively.

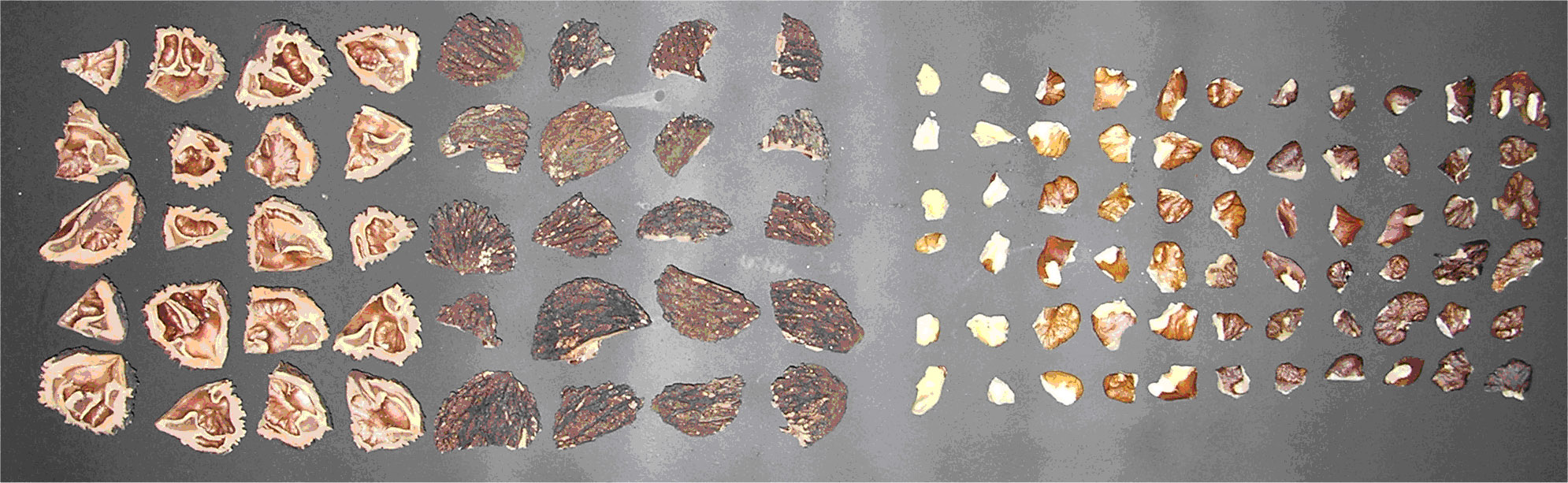

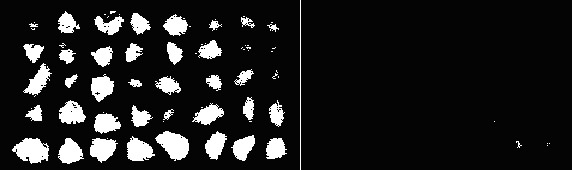

Figure 2. Walnut samples on trays with non-fluorescent black background with (left) nut shell and (right) nut meat.

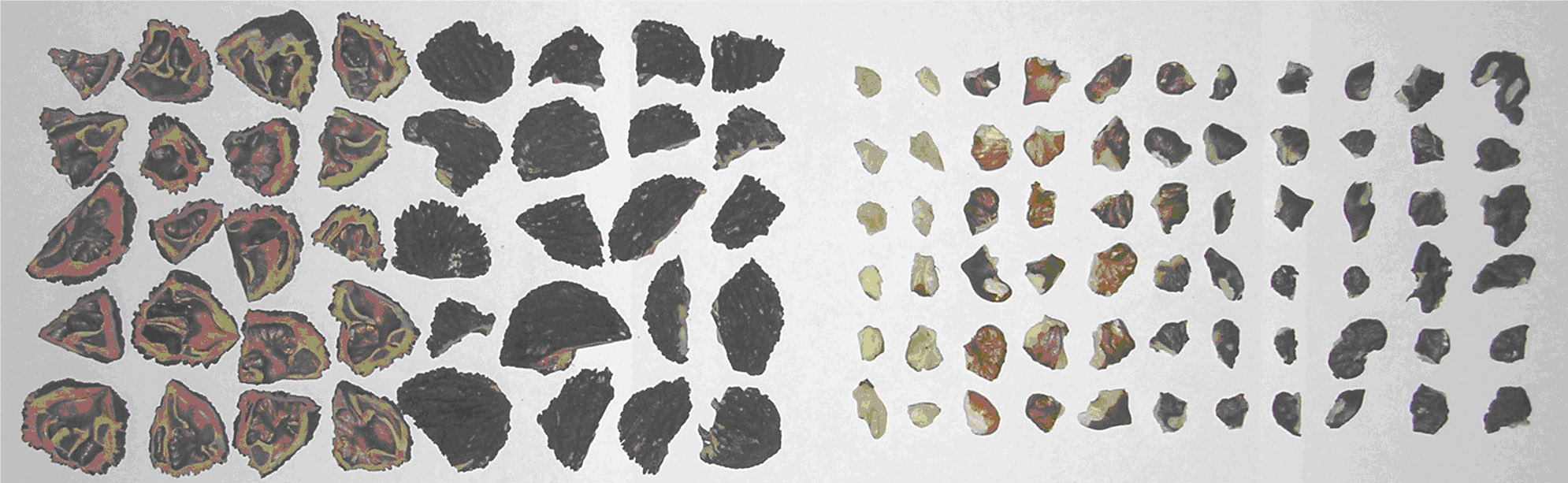

Figure 3. Walnut samples on trays with fluorescent black background with (left) nut shell and (right) nut meat.

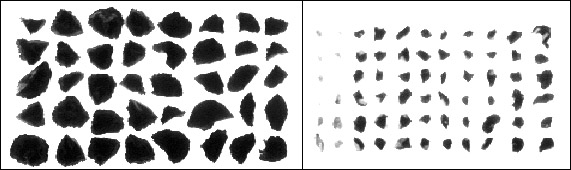

Figure 4. Fluorescence images with white background taken by the hyperspectral imaging system with (left) nut shell and (right) nut meat.

Figure 5. Fluorescence images with fluorescent background taken by the hyperspectral imaging system with (left) nut shell and (right) nut meat.

|

| [Home] [Biography] [Research] [Teaching] [Industry Exp.] [Lab. Personnel] [Collaborators] [Publications] [Links] |